Conveyor Chain

Maniratan Machinery, established in the year 1975, is one of the leading manufacturers of Roller Chains, Conveyor Chains, Peg Chains, Stainless Steel Chains, Extended Pin/Rod Chains, Rubber Top Chains and Biplanar Chain.

We also manufacture specialize chain as per your drawing or sample.

Maniratan Machinery is now an established brand with an excellent track record for the best customer satisfaction. We have never compromised on the quality and the services provided to customer.

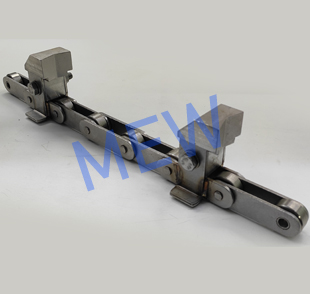

Conveyor Chains

Conveyor chains are fundamental components used in conveyor systems to transport materials or goods from one location to another. These chains are designed to move a series of specially shaped carriers, or attachments, that can hold or secure the materials being transported.

Types of Conveyor Chains :

Conveyor chains are used in various industries to move goods, materials, or products through a manufacturing or processing line depending on the applications.

Common types of Conveyor chains :

Standard or Straight-Link Chains : These are basic chains with rectangular links that resemble common chains. They are used for general purposes.

Hollow Pin Chains : These chains have hollow pins allowing for the insertion of rods or attachments. This feature provides flexibility in attaching various types of materials or products to the chain.

Deep Link Chains : These chains have deeper side plates, which are designed to carry heavier loads. They are commonly used in tough applications where strength is crucial.

Double Pitch Chains : This type has a pitch (the distance between pin centers) twice that of standard chains. They are lighter and often used for slower operations.

Drop Forged Rivet less Chains : They are made from forged steel and lack rivets. This design allows for easy assembly and disassembly. They're used in heavy-duty applications like car assembly lines or grain handling systems.

Flat Top Chains : Made of flat plates, these chains are often used in applications where a stable surface is required to transport products.

Bucket Elevator Chains : Specifically designed for bucket elevators used to elevate bulk materials, these chains have attachments to hold the buckets that carry the material.

Sidewinder Pusher Chains : These are used in systems where products need to be moved to the side, or "pushed" off the main line.

Corrosion Resistant Chains : Made of materials like stainless steel, these chains are used in environments where corrosion is a concern, such as food processing or chemical plants.

Plastic Chains : Used in light-duty applications, these chains are resistant to chemicals and can be used in environments where moisture or contamination is a concern.

Lumber Conveyor Chains : Designed specifically for the forestry industry, these chains are rugged and designed to handle logs and lumber.

Roller Chains : These have rollers which reduce friction and are common in many conveyor and drive applications.

Malleable Iron Chains : Made from malleable iron, these chains are used for their durability and strength.

Engineered Chains : These are custom-designed chains for specific applications, tailored to the unique requirements of a particular industry or operation.

When choosing a conveyor chain, one must consider factors such as the load to be carried, operating environment (temperature, moisture, chemical exposure), speed of operation, and the nature of the goods or materials being transported. Proper selection and maintenance of conveyor chains are critical to ensuring efficient and reliable operation.

Maintenance of Conveyor Chains :

Conveyor chains are essential components in various industries, used to transport materials or products through manufacturing processes. Proper maintenance of these chains ensures longevity, efficient operation, and reduces the potential for unscheduled downtime.

Guidelines and tips for maintaining Conveyor Chains :

Lubrication :

• Regularly lubricate the chain to reduce friction and wear. This will extend the lifespan of both the chain and the sprockets.

• Use the appropriate lubricant for the type of chain and the operating environment. Some chains require special lubricants, especially if they are used in food processing or other sensitive applications.

• Do not over-lubricate as this can attract dirt and other contaminants.

Cleaning :

• Remove accumulated debris, dirt, or contaminants regularly. These can increase wear and potentially damage the chain.

• For chains used in food or pharmaceutical processing, ensure they are cleaned to meet industry standards and regulations.

Inspection :

• Regularly check chains for wear, elongation, or damage. A chain that has elongated by 3% or more of its original length should be replaced.

• Examine sprockets for wear. Worn sprockets can reduce the efficiency of the chain and lead to premature failure.

• Look for broken or damaged links, which should be replaced immediately.

Tension and Alignment :

• Maintain proper chain tension. Overly tight chains can lead to increased wear and power loss, while slack chains can cause skipping or derailment.

• Ensure that the conveyor's sprockets are properly aligned to prevent uneven wear and potential binding of the chain.

Replace Worn Components :

• Chains, sprockets, and other components have a finite lifespan. Replace parts that are overly worn or damaged to ensure the conveyor operates efficiently.

• When replacing chains, consider replacing the sprockets simultaneously. A new chain on a worn sprocket can lead to accelerated wear on the new chain.

Avoid Overloading :

• Ensure the conveyor is not overloaded, as this can lead to increased wear and the potential for chain failure.

• Regularly check the maximum load capacity of the chain and ensure it's not exceeded.

Environmental Considerations :

• If the conveyor operates in a corrosive or high-humidity environment, consider using chains made of corrosion-resistant materials.

• In abrasive environments, make sure to regularly clean the chains and consider using wear-resistant chain designs or materials.

Safety :

• Always lockout and tagout the conveyor system before performing maintenance.

• Wear appropriate personal protective equipment (PPE) when working on or around conveyor systems.

Training :

• Ensure maintenance personnel are adequately trained to handle conveyor chain maintenance, including understanding the manufacturer's specifications and recommendations.

By adopting a proactive approach to conveyor chain maintenance, you can significantly extend the life of the chain, improve operational efficiency, and reduce costly downtime.

Conveyor Chains application industries :

Conveyor chains are critical components in a wide range of industries and applications. They are used to move materials, products, or components from one location to another efficiently. Here are some of the primary industries and applications that utilize conveyor chains :

Manufacturing and Assembly Lines : These chains are used to move parts and finished products in factories and production facilities.

Food and Beverage : Conveyor chains transport raw materials, ingredients, and finished food products. They must often meet sanitary requirements in these industries.

Automotive : Used in the assembly of vehicles and transportation of parts.

Pharmaceuticals : They transport materials and finished products in a clean and precise manner.

Mining : Conveyor chains are used to move mined materials like coal, ores, and minerals.

Agriculture : Used to move grains, feeds, and other agricultural products.

Packaging : Conveyor systems package goods and transport them for shipping.

Electronics : Moving components and finished devices.

Warehousing and Distribution : These chains are used in automated storage and retrieval systems (AS/RS) and in the distribution centers to move goods.

Pulp and Paper : They help in the transportation of logs, pulp, and finished paper products.

Textiles : Used in the transportation and processing of textiles in factories.

Forestry : Chains can transport logs in sawmills and other forestry applications.

Waste Management and Recycling : They are used to sort, separate, and transport waste materials.

Aerospace : Used in the manufacturing and assembly processes of aircraft and parts.

Cement Production : Used to transport raw materials like limestone and finished cement.

Bottling Plants : Conveyors move bottles through filling, capping, and labeling processes.

Chemical Industry : For moving chemical containers or materials from one process to another.

Retail : Especially in large distribution centers where goods are sorted for shipping to individual stores.

Mail and Parcel Distribution : Conveyor chains help in the sorting and distribution of mail and parcels, particularly in large distribution centers.

Escalators : While not a traditional industry, it's worth noting that the moving steps of escalators are a type of conveyor system, operated by chains.

The design and specification of the chain will vary based on the specific requirements of each industry and application, such as load-bearing capacity, speed, environmental conditions, and cleanliness standards.

When selecting a conveyor chain for a specific application, consider factors like the type of material being transported, the environment (e.g., is it wet, acidic, high temperature?), the speed and load requirements, and the desired lifespan of the chain. It's often wise to consult with experts or manufacturers to get the most appropriate chain for a specific application.