Standard Chain

One of the top producers of roller chains, conveyor chains, peg chains, stainless steel chains, extended pin/rod chains, rubber top chains, and biplanar chains is Merit Engineering Work, which was founded in 1975.

Additionally, we can create specialized chains based on your sample or drawing.

Today, Merit Engineering Work is a well-known brand with a stellar reputation for providing the highest level of client satisfaction. We have never sacrificed the caliber of the services we offer our clients.

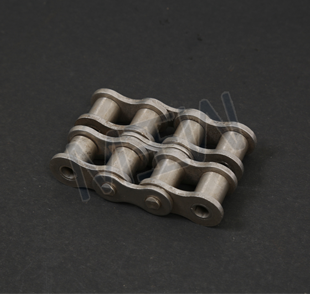

Standard Chain

One popular kind of roller chain used in mechanical power transmission is the Standard Chain. It is made up of several interconnected plates, rollers, bushings, and pins. These chains' longevity, effectiveness, and capacity to transfer power over great distances make them popular in industrial machines, conveyors, bicycles, and motorbikes.

Types of Standard Chain :

Usually composed of nickel-plated steel, stainless steel, or carbon steel. utilized in sectors such as food processing, construction, automotive, and agriculture. has to be lubricated and inspected on a regular basis to avoid wear and failure. The ideal chain selection is determined by load capacity, speed, environment, and application type.

- Roller Chain : Most commonly used for power transmission in machinery, vehicles, and conveyors.

- Double Pitch Roller Chain : Features an extended pitch for lighter loads and lower speeds.

- Heavy-Duty Roller Chain : Designed for high-load and high-impact applications.

- Silent Chain : Provides smooth and quiet operation, often used in engines and precision machinery.

- Leaf Chain : Made of stacked plates, used in forklifts, hoists, and lifting applications.

- Conveyor Chain : Used for material transport in manufacturing, food processing, and mining.

- Hollow Pin Chain : Has hollow pins for easy attachment of components or accessories.

- Side Bow Chain : Allows for lateral movement, making it ideal for curved conveyors.

- Agricultural Chain : Specifically designed for farming equipment like harvesters and tillers.

- Detachable Chain : Easy to assemble and disassemble, commonly used in light-duty conveyors.

- Offset Link Chain : Features offset links for easy length adjustments in power transmission.

- Double-Strand Roller Chain : Offers increased strength and durability for heavy loads.

- Triple-Strand Roller Chain : Used in extremely heavy-duty power transmission applications.

- Welded Steel Chain : Made for rugged environments such as forestry, mining, and construction.

- Pintle Chain : Used in conveyors for bulk material handling, especially in agriculture and wastewater treatment.

Maintenance of Standard Chain :

To guarantee longevity and smooth performance, a Standard Chain needs to be cleaned, lubricated, and have its tension adjusted on a regular basis. Check for corrosion, wear, and misalignment, and replace any broken links. When machinery or vehicles are properly maintained, friction is reduced, breakage is avoided, and efficiency is increased.

Guidelines and tips for maintaining Standard Chain

- Clean Regularly : Remove dirt, dust, and debris to prevent buildup and wear.

- Lubricate Properly : Use the recommended lubricant to reduce friction and prevent rust.

- Maintain Correct Tension : Avoid excessive slack or tightness to ensure smooth operation.

- Inspect for Wear & Tear : Check for elongation, cracks, rust, or damaged links.

- Avoid Overloading : Do not exceed the chain’s load capacity to prevent breakage.

- Store Properly : Keep chains in a dry, clean environment to prevent corrosion.

- Check Sprockets & Gears : Ensure proper alignment and replace worn-out sprockets.

- Tighten Loose Fasteners : Regularly inspect and secure bolts, nuts, and connecting links.

- Prevent Contamination : Keep the chain free from chemicals, water, and abrasive materials.

- Rotate Chains When Possible : If multiple chains are used, rotate them for even wear.

- Monitor Temperature : Excessive heat can weaken the chain; ensure proper cooling.

- Use High-Quality Replacement Parts : Replace worn-out links with durable, compatible parts.

- Follow Manufacturer’s Guidelines : Adhere to the recommended maintenance schedule.

- Perform Regular Alignment Checks : Ensure proper chain and sprocket alignment to prevent uneven wear.

- Schedule Periodic Professional Inspection : Get expert evaluation to ensure long-term reliability.

Standard Chain Application Industries :

- Automotive Industry : Used in engines, transmission systems, and conveyors.

- Agriculture : Essential for tractors, harvesters, and irrigation systems.

- Manufacturing & Industrial Machinery : Applied in conveyors, assembly lines, and robotics.

- Construction : Used in lifting equipment, cranes, and hoisting systems.

- Food & Beverage Processing : Employed in food conveyors and packaging machines.

- Mining & Quarrying : Used in heavy-duty machinery, crushers, and conveyors.

- Power Transmission : Vital for gear mechanisms and drive systems.

- Textile Industry : Applied in weaving machines, looms, and textile conveyors.

- Pharmaceutical Industry : Used in sterile conveyor systems for drug manufacturing.

- Aerospace & Aviation : Found in aircraft maintenance equipment and conveyor systems.

- Oil & Gas Industry : Used in drilling rigs, pumps, and pipeline systems.

- Steel & Metal Processing : Essential for rolling mills and metal conveyor systems.

- Logistics & Warehousing : Applied in automated storage and retrieval systems.

- Railways & Transportation : Used in signaling, lifting mechanisms, and conveyors.

- Marine & Shipbuilding : Found in anchor mechanisms, winches, and lifting systems.